21. July 2022 12:32

/

Titanium

/

Comments (0)

Tiaano®, a design and manufacturing Shell and Tube Heat exchangers by using Inert metals of Titanium, Tantalum, Niobium, Zirconium, Nickel, Hastelloy, Duplex SS etc. Titanium is used as the material of construction for Heat Exchangers in chemical, petrochemical, oil & gas and other industrial manufacturing environments. Titanium goes into corrosion-resistant equipment fabrication than all other reactive metals combined.

Heat exchangers are designed and built for efficient heat transfer from one medium to another. Tiaano performs all thermal and mechanical designs of shell and tube heat exchangers in-house. We often present our customers with effective cost and delivery solutions that are not apparent when dealing with other more common materials.

Tiaano Engineers design and manufacture and supply highly corrosion-resistant process equipment for any industry that has corrosion problems. We cater to the following Industries:

· Chemical

· Petrochemical

· Oil & Gas Liquefied Natural Gas (LNG)

· Pharmaceutical

· Steel Industry

· Energy

· Biomass

· Nuclear Power

· Solar Power Facilities

· Metal Finishing, Plating & Anodizing

· Mining

· Water Desalination

c341e52f-05df-4373-82c5-bf9fa8ada81d|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

Tiaano®, a design and manufacturing Shell and Tube Heat exchangers by using Inert metals of Titanium, Tantalum, Niobium, Zirconium, Nickel, Hastelloy, Duplex SS etc. Titanium is used as the material of construction for Heat Exchangers in chemical, petrochemical, oil & gas and other industrial manufacturing environments. Titanium goes into corrosion-resistant equipment fabrication than all other reactive metals combined.

Heat exchangers are designed and built for efficient heat transfer from one medium to another. Tiaano performs all thermal and mechanical designs of shell and tube heat exchangers in-house. We often present our customers with effective cost and delivery solutions that are not apparent when dealing with other more common materials.

Tiaano Engineers design and manufacture and supply highly corrosion-resistant process equipment for any industry that has corrosion problems. We cater to the following Industries:

· Chemical

· Petrochemical

· Oil & Gas Liquefied Natural Gas (LNG)

· Pharmaceutical

· Steel Industry

· Energy

· Biomass

· Nuclear Power

· Solar Power Facilities

· Metal Finishing, Plating & Anodizing

· Mining

· Water Desalination

http://www.ptanode.com/post/Ionization-Mesh-Electrode.aspx

889c71e3-a6d2-4aef-b344-39e6345887fe|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

Ti Anode Fabricators Pvt Ltd has an internationally recognized reputation for the manufacture of the Titanium GR.2 Tube. Titanium Gr 2 Tube is considered to be the ideal alloy choice for most industrial applications which require properties such as good ductility and corrosion resistance. Titanium Gr 2 Sanitary Tube offers excellent resistance to seawater and marine atmospheric corrosion as well.

The density of titanium tubes is significantly lower than steel, copper, or nickel products. Despite their low density, they are very strong and rigid when compared to other alloy components. Another benefit of utlizing titanium tubing is that titanium alloys are resistant to corrosion. This makes these tubes an appealing option if you need a part to work efficiently in a high corrosive environment. Corrosion is not the only thing that titanium tubes are resistant to. They are also resistant to chemicals. These titanium parts can withstand different chemical compounds while still preforming effectively. Titanium tubes have great heat transfer properties because of its thermal conductivity and resistance. The same can't be said for copper and carbon steel tubes. Their resistance to heat also allows them to work successfully at tempeartures up to 600 degrees or higher.

Our sincere team of professionals and employees are always making an extensive effort to make high range of qualitative products which can be completely satisfy the expectations of our reliable consumers. We are proficiency in ethical to the equipment demands in diverse industries including Power, Oil & Gas, and Chemical, Water & Waste Water Treatment, Food, Pharma and others.

6c48e541-64cc-4d86-9327-f2c6ed5432b1|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

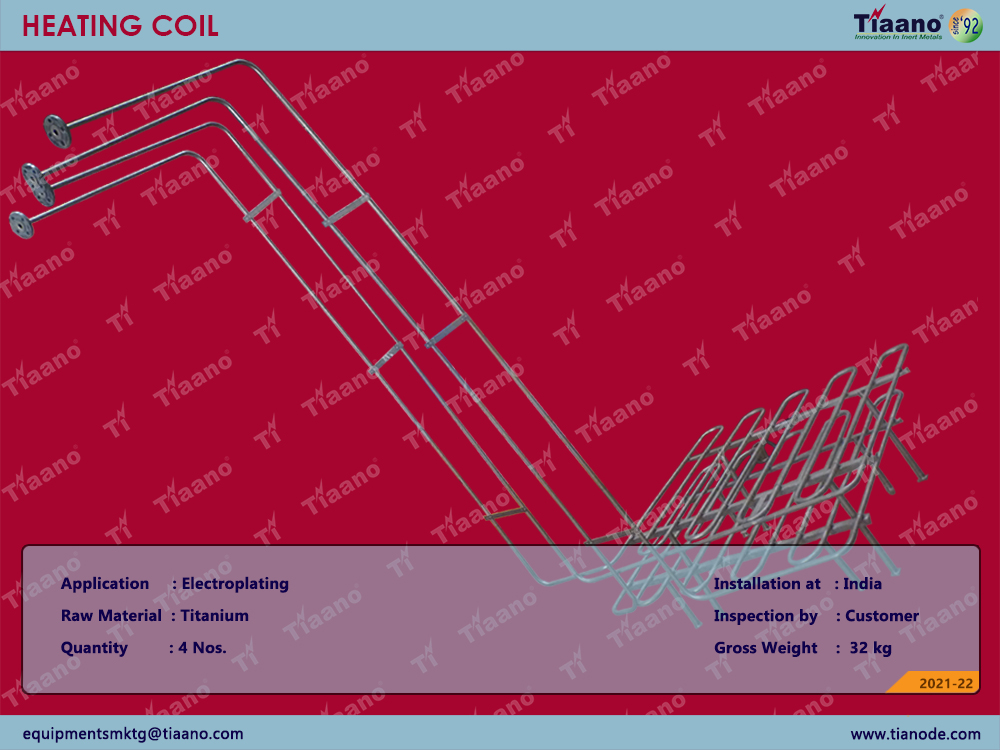

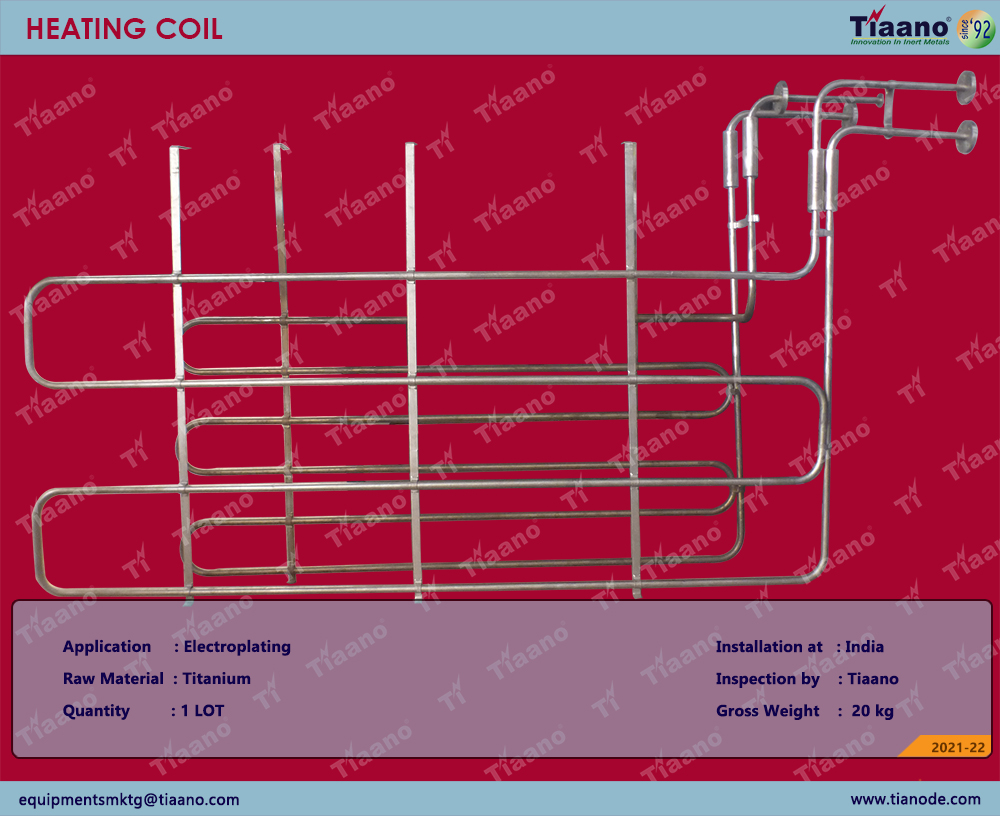

Ti Anode Fabricators Pvt Ltd has an internationally recognized reputation for the manufacture of the Titanium Electro Plating Heating Coil. Heating coil is used where steam or thermic fluid is used for large scale plating industrial operation. Tiaano offers electro plating industrial coils in various material of construction which suits for your electro-chemical plating process.

It can be supplied in various Shapes as per customer requirement. Typical Applications are as a Cooling Coil in Acid Zinc, Acid Copper and also Hard Chrome Baths. Tiaano is well versed in doing repair work of heating coil and it is in wide range in manufacturing the Titanium heating coil. Corrosion resistant coils are also manufactured to help match corrosion and chemical erosion solution.

Whether the factory environment is acidic or alkaline, salt-laden, or de-ionized, we have the capability to select the proper combination of materials to match your duty requirements. Tiaano efficiently manufactures a wide range of coil sizes and dimensions.

Our sincere team of professionals and employees are always making an extensive effort to make high range of qualitative products which can be completely satisfy the expectations of our reliable consumers. We are proficiency in ethical to the equipment demands in diverse industries including Power, Oil & Gas, and Chemical, Water & Waste Water Treatment, Food, Pharma and others.

993fed71-0a65-4c7e-86f9-7989f911c3ee|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

Ti Anode Fabricators Pvt Ltd has an internationally recognized reputation for the manufacture of the Titanium Anode Basket. Tiaano’s titanium Anode Baskets are fabricated from the finest grade of titanium and are very durable. Titanium Baskets have an excellent finish and are designed with the sides and base made from a solid sheet and the hooks welded to ensure good electrical conductivity. Anode baskets can be made in all grades of titanium depending on the application.

Tiaano fabricates larger, non-standard sizes and round baskets. The non-standard baskets include Spiral anode baskets in various lengths, Conforming Anode baskets for Barrel plating, Reel to Reel Plating Baskets, Special Application Baskets. Tiaano also fabricates titanium hooks and plating accessories for almost all type of plating industries. Titanium Anode Baskets are used for holding the plating anodes.

Titanium anode baskets offer a number of benefits that make them preferable over other types of materials. They are:

· Non-corrosive

· Lightweight

· Durable

· Very strong

They also have Uniform current distribution, Uniform anode area, high anode efficiency, Less voltage loss and Constant deposition.

Our sincere team of professionals and employees are always making an extensive effort to make high range of qualitative products which can be completely satisfy the expectations of our reliable consumers. We are proficiency in ethical to the equipment demands in diverse industries including Power, Oil & Gas, and Chemical, Water & Waste Water Treatment, Food, Pharma and others.

b045331a-497c-407f-b687-8c39f91e6b08|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

Ti Anode Fabricators Pvt Ltd has an internationally recognized reputation for the manufacture of the Titanium Electro Plating Heating Coil. Heating coil is used where steam or thermic fluid is used for large scale plating industrial operation. Tiaano offers electro plating industrial coils in various material of construction which suits for your electro-chemical plating process.

It can be supplied in various Shapes as per customer requirement. Typical Applications are as a Cooling Coil in Acid Zinc, Acid Copper and also Hard Chrome Baths. Tiaano is well versed in doing repair work of heating coil and it is in wide range in manufacturing the Titanium heating coil. Corrosion resistance coils are also manufactured to help match corrosion and chemical erosion solution.

Whether the factory environment is acidic or alkaline, salt-laden, or de-ionized, we have the capability to select the proper combination of materials to match your duty requirements. Tiaano efficiently manufactures a wide range of coil sizes and dimensions.

Our sincere team of professionals and employees are always making an extensive effort to make high range of qualitative products which can be completely satisfy the expectations of our reliable consumers. We are proficiency in ethical to the equipment demands in diverse industries including Power, Oil & Gas, and Chemical, Water & Waste Water Treatment, Food, Pharma and others.

37ca945f-b812-44de-9e05-2920811f4e82|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

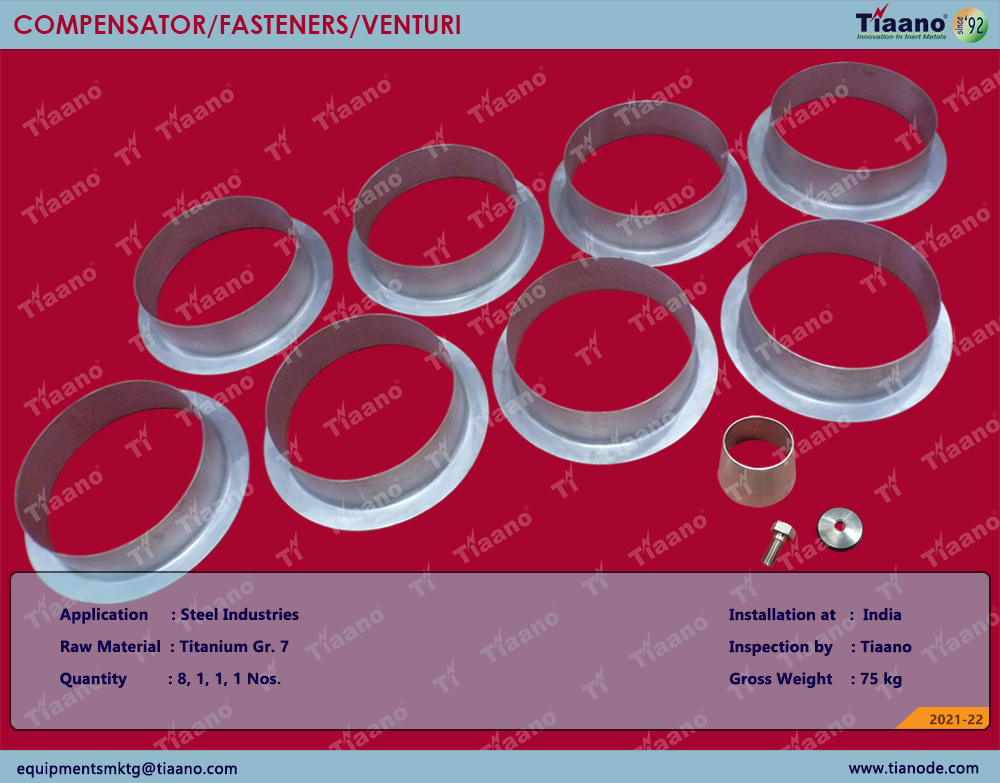

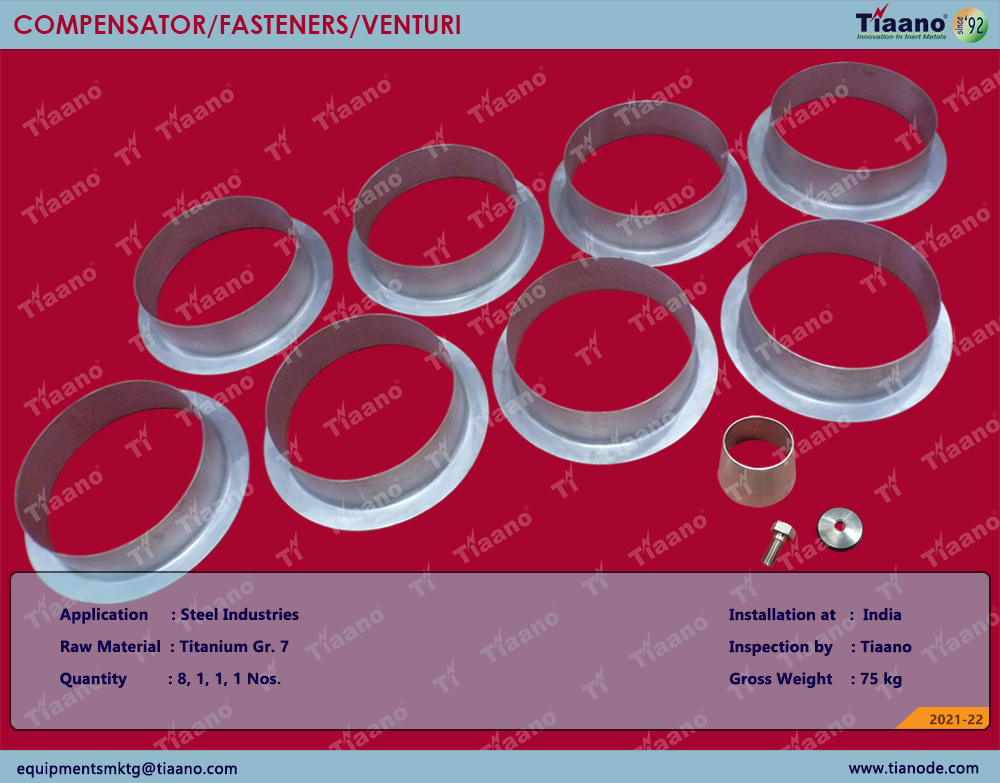

Ti Anode Fabricators Pvt Ltd has an internationally recognized reputation for the manufacture of the Titanium Fasteners. Titanium Grade 7 fasteners are used in applications where high strength to weight ratio, excellent resistance to stress corrosion cracking, high corrosion resistance, and good fatigue strength are desired.

The mechanical properties of titanium will vary depending on the grade used. For instance, Titanium Bolts and Fasteners produced from alloys grade 1, grade 2, grade 3 and grade 4 are referred to as commercially pure titanium grades. Grade 7 possesses excellent corrosion resistance of all titanium alloys. In fact, it is most resistant to corrosion in reducing acids. Grade 7 is used in chemical processes and production equipment components.

Our sincere team of professionals and employees are always making an extensive effort to make high range of qualitative products which can be completely satisfy the expectations of our reliable consumers. We are proficiency in ethical to the equipment demands in diverse industries including Power, Oil & Gas, and Chemical, Water & Waste Water Treatment, Food, Pharma and others.

e165b872-6e87-4572-979d-0f75fc3f15b1|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

Ti Anode Fabricators Pvt Ltd has an internationally recognized reputation for the manufacture of the Titanium Compensator. A compensator is a component in the control system and it is used to regulate another system. In most of the time, it is done by conditioning the input or the output to that system. There are three types of compensators: lag, lead and lag-lead compensators.

Benefits of compensators allow faster, more accurate follow up shots and generally tighter groupings. Compensator made in Titanium Grade 7 is highly corrosion resistance.

Our sincere team of professionals and employees are always making an extensive effort to make high range of qualitative products which can be completely satisfy the expectations of our reliable consumers. We are proficiency in ethical to the equipment demands in diverse industries including Power, Oil & Gas, and Chemical, Water & Waste Water Treatment, Food, Pharma and others.

ada9b5b9-6d02-4609-92c0-3bf2c42f6d35|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

Ti Anode Fabricators Pvt Ltd has an internationally recognized reputation for the manufacture of the Titanium GR.7 Venturi. Venturi is used to measurethe speed of a fluid, by measuring the pressure changes from one point to another along the venture. A Venturi can also be used to inject a liquid or a gas into another liquid.

Advantages of Venturi smooth construction and low cone angle help to solid particles flow through it. So it can be used for dirty fluids. It can be installed in any direction horizontal, vertical and inclined. More accurate than orifice and flow nozzle. There is less chance of getting stuck with sediment. The discharge coefficient is high. Its behavior can be predicted perfectly. It can be installed vertically, horizontally, inclined.

Our sincere team of professionals and employees are always making an extensive effort to make high range of qualitative products which can be completely satisfy the expectations of our reliable consumers. We are proficiency in ethical to the equipment demands in diverse industries including Power, Oil & Gas, and Chemical, Water & Waste Water Treatment, Food, Pharma and others.

16962729-8c15-44b1-8c77-1163f932bb5e|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

Ti Anode Fabricators Pvt Ltd has an internationally recognized reputation for the manufacture of the Tantalum Seam weld Sleeve. Ti Anode Fabricators Pvt Ltd offers the Seam weld Sleeves for thermo well and Sensor Safety pocket out of Tantalum, Niobium, Zirconium, Titanium, Titanium Palladium alloy (Titanium Gr.7), Molybdenum, Ceramic, PTFE or Teflon, Nickel and its alloys like Hastelloy B, B2, & C, Inconel, Monel, Nicrofer etc. They are all precision made to the highest standards of finish in our modern well equipped machine shop.

Our sincere team of professionals and employees are always making an extensive effort to make high range of qualitative products which can be completely satisfy the expectations of our reliable consumers. We are proficiency in ethical to the equipment demands in diverse industries including Power, Oil & Gas, and Chemical, Water & Waste Water Treatment, Food, Pharma and others.

421ae0c7-380f-42c0-bf93-3934251db2a0|0|.0|27604f05-86ad-47ef-9e05-950bb762570c