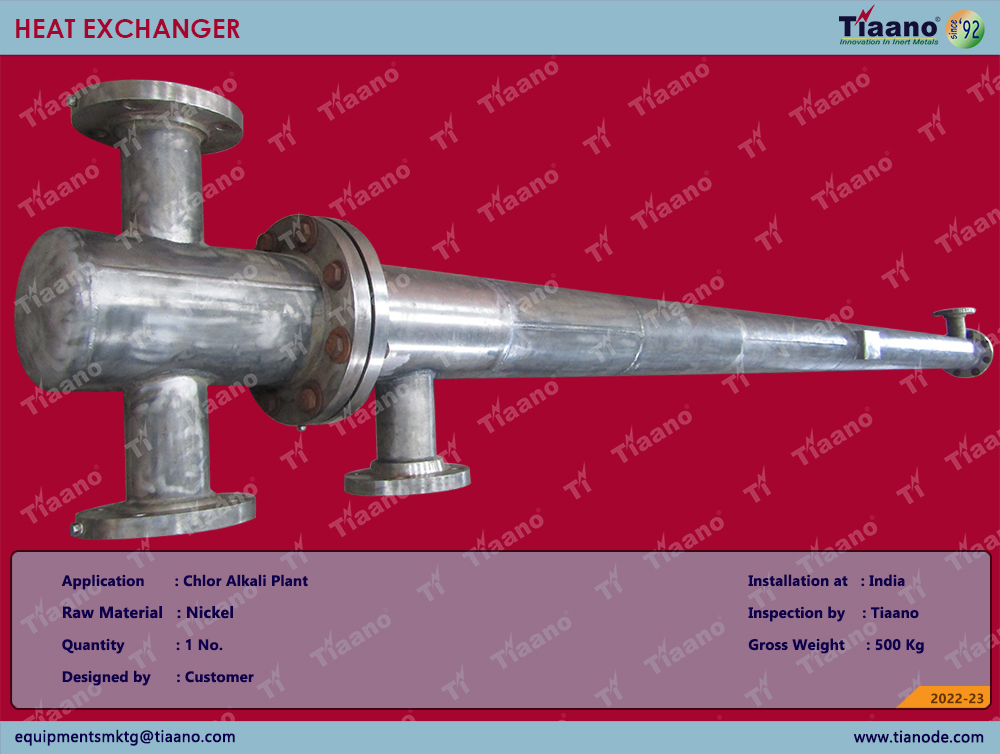

Ti Anode Fabricators Pvt Ltd has an internationally recognized reputation for the manufacture of the Nickel Heat Exchanger. Nickel Heat Exchanger is another type of heat exchanger that is widely used in chemical processing industry.

This type of heat exchanger consists of a shell filled with a bundle of tubes and sealed with each end with the tube sheet that isolates the shell and the tubes. Heat exchangers are the device that is used for transferring fluids.

Some of the most important components in many industrial applications are heat exchangers. These are systems that are designed to transfer heat from one fluid to another for either heating or cooling. Heat exchangers enable heat from one liquid or gas to pass to another liquid or gas without the two substances coming into direct contact.

Heat exchangers are found in power plants, chemical processing plants, petrochemical production plants, waste treatment systems, and oil and gas processing, for example. The nuclear industry also uses heat exchangers to help cool or heat its systems. In addition, several quality tests are done to check the durability and quality of the heat exchangers. The testing includes a hydrostatic test, UT test, non-destructive test, pressure testing, corrosion resistance and more as per the demand. All the tests are done as per the set rules and regulations under the supervision of experts.

Our sincere team of professionals and employees are always making an extensive effort to make high range of qualitative products which can be completely satisfy the expectations of our reliable consumers. You can avail this range of Clamps at a very reasonable price and with customer customization. We are proficiency in ethical to the equipment demands in diverse industries including Power, Oil & Gas, and Chemical, Water & Waste Water Treatment, Food, Pharma and others.

Enquiry

For any inquiry in regards to Nickel Heat Exchanger please contact us on +91 8438164458 or email us on equipmentsmktg@tiaano.com.

b74b5e36-45ce-4e01-adb8-7f585136279e|0|.0|27604f05-86ad-47ef-9e05-950bb762570c