Nickel 201 Caustic Distribution Channel – This will be fabricated from Ni.201 plates & it will be used in the Caustic Concentration division in Caustic Soda Plants. Here tubes made of low carbon nickel alloy 201 (EN 2.4068/UNS N02201) should be used because at temperatures higher than about 315 °C (600 °F) the higher carbon content of the standard nickel grade alloy 200 (EN 2.4066/UNS N02200) can lead to graphite precipitation at the grain boundaries. Caustic soda has an aggressive impact on most metallic materials, especially at high temperatures and concentrations. It has been known for a long time, however, that nickel exhibits excellent corrosion resistance to caustic soda at all concentrations and temperatures. In addition, except at very high concentrations and temperatures, nickel is immune to caustic-induced stress-corrosion cracking. The nickel standard grades alloy 200 (EN 2.4066/UNS N02200) and alloy 201 (EN 2.4068/UNS N02201) are therefore used at these stages of caustic soda production, which require the highest corrosion resistance. Since Caustic soda (NaOH) is one of the most important chemical feedstocks, with a total annual production of 106t. NaOH is used in organic chemistry, in the production of aluminum, in the paper industry, in the food processing industry, in the manufacture of detergents, etc. Nickel is the preferred material of construction for caustic soda distribution trays where the austenitic steels cannot be used.

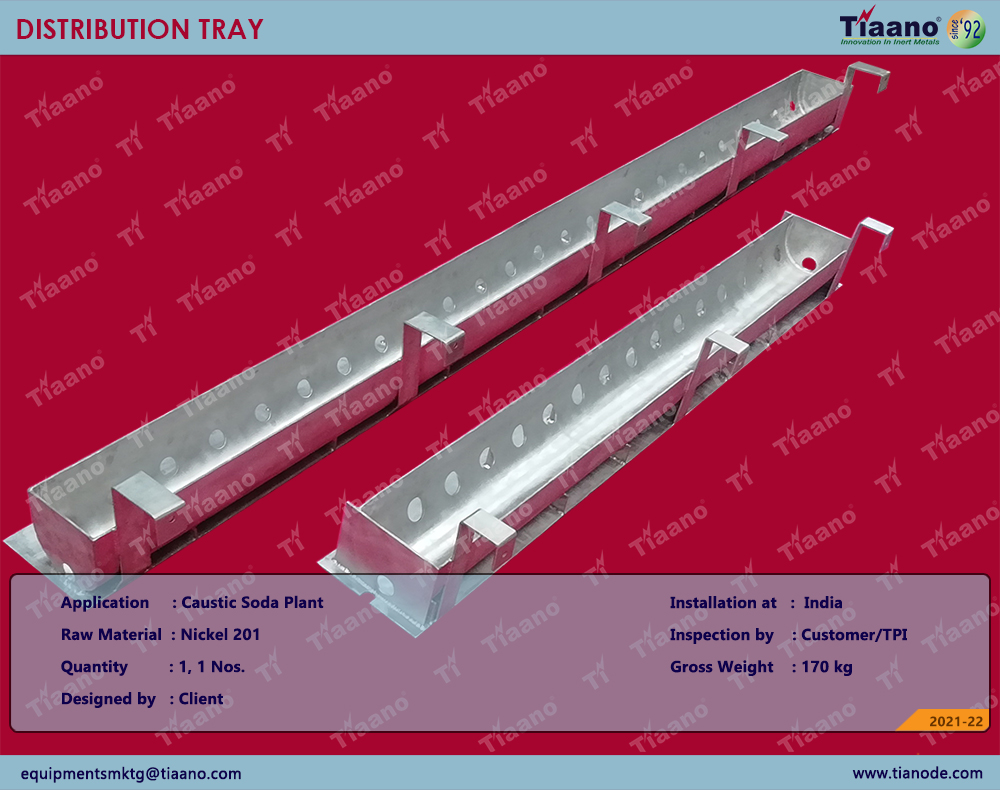

Recently we have supplied the caustic soda distribution tray to one of our valuable customers and the product photo is attached below

MANUFACTURING OF CAUSTIC SODA DISTRIBUTION TRAY

To know more details Please feel free to visit our website: - www.tianode.com

Follow Us on Instagram , twitter, Facebook, Pinterest

de64c5d8-407c-40bc-ba60-a1b1d2b56dbc|0|.0|27604f05-86ad-47ef-9e05-950bb762570c