| |

|

TITANIUM Anodes & NICKEL Cathodes for CHLOR ALKALI INDUSTRY

|

Tiaano® a leading design and fabrication company established in 1992 with well-equipped in plant facilities and qualified engineers, delivers DSA Titanium anodes and Nickel cathodes – both Refurbishment, Recoated and Zero gap Retrofitting by using Precious metal oxides of… Iridium, Ruthenium, Palladium etc. / ENGINEERING equipment and TURNKEY projects from the single platform by using inert metals.

Tiaano® a leading design and fabrication company established in 1992 with well-equipped in plant facilities and qualified engineers, delivers DSA Titanium anodes and Nickel cathodes – both Refurbishment, Recoated and Zero gap Retrofitting by using Precious metal oxides of… Iridium, Ruthenium, Palladium etc. / ENGINEERING equipment and TURNKEY projects from the single platform by using inert metals.

* Tiaano has been undertaking refurbishment and recoating chlor alkali electrodes since 1994.

* Tiaano’s coatings are working more than a decades in…

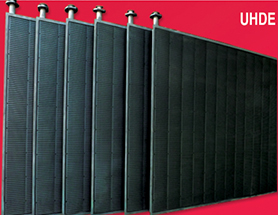

* UHDE / UHDENORA / DENORA / CEC’s Cells.

* INEOs / ICI’s Cells

* ELTECH / OXYTECH / DENORATECH’s Cells

* Undertaking the refurbishment and recoating of anode. Coatings warranty starts from minimum of 6 years, maximum 10 years according to the current density.

* Tiaano preparing Metal Oxides in its own refinery from the precious metal sponge.

* servicing to the worldwide chlor alkali industries

* including USA, IRAN, UAE, SAUDI ARABIA & INDIA.

Reactors, Pressure vessels, Storage tanks, Column, Blowers, Mixers, Anolyte & Catholyte headers, Pumps, Valves, Pipe fittings, Thermowells and Fasteners by using inert metals of Titanium, Nickel, Monel, Tantalum, Niobium, Zirconium, Hastelloy, Duplex SS, Molybdenum & their alloys.

|

|

|