|

|

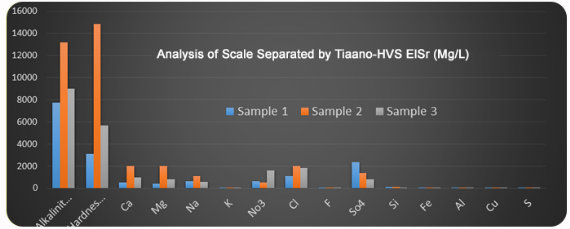

Continuous scale / hardness removal and onsite disinfectants generation - mitigate the scaling, corrosion, bio-fouling & bacterial infection in Cooling Tower Water Distribution System. In order to overcome the limitations of conventional cooling water treatment (addition of chemicals or by water softening), Tiaano ventrued with M/s. HVS, Singapore and developed “Tiaano-HVS ElSr” – removal or separation of scale/hardness by electrlytic opeation. Tiaano-HVS Elsr produces Oxidents in the water; Oxidants prevents the Corrosion, Bio-fouling, Scaling, Micro-Organism growth & spread of airborne bacteria.

|

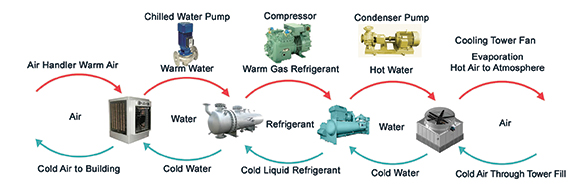

| Cooling Tower Operation:

|

|

| How Tiaano-HVS ElSr works:

|

- Accelerated scale precipitation within a reactor.

- Production of active alkaline ionic species - enabling automatic active pH manipulation to control corrosion.

- Continuous online generation of active oxidants - as a replacement to biocides and oxidising agents.

|

|

| Technical Innovation:

|

- Proprietary Ultra-Short Pulsed DC Technology.

- Highly Efficient Oxidation - Reduction Process.

- Cold Electrochemical Activation System.

- Functionalised Electrodes Design.

- Self-Cleaning Electrodes.

|

| Potential Benefits for Cooling Tower operation:

|

- 100% savings on chemicals.

- 70 ~ 100% savings on blowdown water.

- 10 ~ 50% savings on labour cost.

- 20 ~ 40% of water savings.

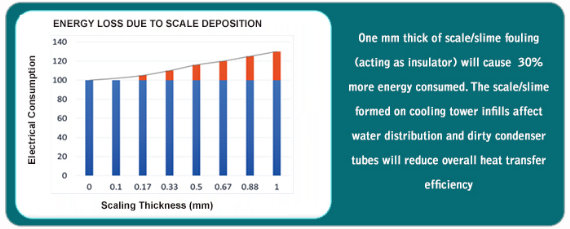

- 05 ~ 15% of energy savings of cooling fan.

- 02 ~ 04% energy savings of chiller.

|

| Advantages over existing non-chemical treatment system:

|

- Green technology.

- Zero Bleed Loss.

- Low energy Consumption.

- Modular design.

- Zero Toxic Sewer Load.

- No toxic chemical storage hazard.

- Small footprint.

- Easy operation.

- Low maintenance.

|

|