Ti Anode Fabricators Pvt Ltd has an internationally recognised reputation for the design and manufacture of FASTENER. We are one of the trustworthy manufacturers, exporters, dealers, and suppliers of FASTENER. Wide ranges of Fastener are offered by Tiaano is manufactured with durable and corrosion-resistant materials to perform in the harsh environments found in the chemical processing industry. A Fastener or Fastening is a hardware device that mechanically joins or affixes two or more objects together. In general, fasteners are used to create non-permanent joints, that is, joints that can be removed or dismantled without damaging the joining components. Welding is an example of creating permanent joints. Steel fasteners are usually made of stainless steel, carbon steel, or alloy steel, manufactured in-house from traceable metals, are in precision made to the usual international standards. A threaded fastener has internal or external screw threads. The most common types are the screw, nut and bolt, possibly involving washers. Given mentioned photographs shows TAF' efficiency and experience.

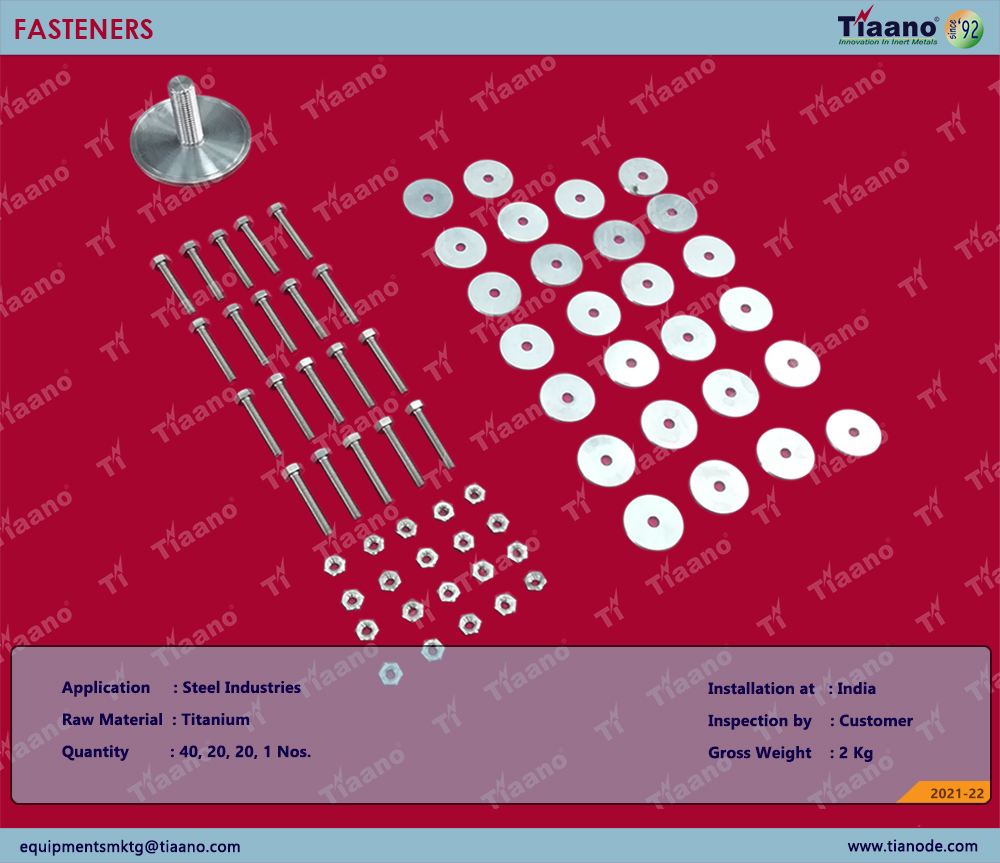

Recently we have supplied Fastener to one of our valuable customer and the product photo is attached below.

Fastener are made from Titanium, Tantalum, Nickel, Zirconium, Hastelloy are our main focus.

Application:

When selecting a fastener for industrial applications, it is important to consider various factors such as threading, the applied load on the fastener, the stiffness of the fastener, and the number of fasteners needed.

When choosing a fastener for a given application, it is important to know the specifics of that application to help us select the proper material for the intended use. Factors that should be considered are:

· Accessibility,

· Environment, including temperature, water exposure, and potentially corrosive elements.

· Installation process,

· Materials to be joined,

· Reusability,

· Weight restrictions.

To know more details Please feel free to visit our website: - www.tianode.com

Follow Us on Instagram , twitter, Facebook, Pinterest

d415849b-1570-4e5a-b038-728165f629fb|0|.0|27604f05-86ad-47ef-9e05-950bb762570c