We produce high-quality Titanium mesh. Titanium Wire Meshes are highly resistant to the corrosive environment. We can produce Titanium mesh with titanium TA1 or TA2 or by customer’s requirement. Grade 2 is the commercially pure titanium used in most chemical processing plants and is cold-formable. Grade 2 plate and sheet can have an ultimate tensile strength at and above 40,000 psi. Grade 5 is aerospace-grade and is not cold-formable, so it is used more often when no forming is needed. Selected for its unique combination of high strength, lightweight, corrosion resistance, bio-compatibility, and higher temperature performance.

Titanium Wire Mesh possesses a silver-white appearance. Titanium mesh has significant durability, lightweight, and corrosion resistance properties. Generally, commercially pure titanium is utilized in anodizing applications. Wire mesh is commonly used in industrial applications when separation or filtration is needed.

Titanium mesh offers extensive resistance to saltwater and is virtually immune to natural corrosion. It prevents the attack of metallic salts, chlorides, hydroxides, nitric and chromic acids, and dilutes alkalis. Titanium mesh can be white or black depending on if the wire drawing lubricants are discarded from its surface or not.

Titanium Mesh Applications:

Titanium mesh is used in many applications, such as seawater- shipbuilding, military, mechanical industry, chemical, petroleum, pharmaceutical, medicine, satellite, aerospace, environmental industry, electroplating, battery, surgery, filtration, mechanical filter, oil filter, electromagnetic shielding, electric, power, water desalination, heat exchanger, energy, paper industry, titanium electrode, etc.

Features: -

# Light weight

# Twice as stronger as steel

# Electrical and thermal conductivity

# Resistant to saltwater/seawater

# Resistant to corrosion caused by the weather/atmospheric condition

# Resistant to other chemical compounds such as chlorides, nitric and metallic salts

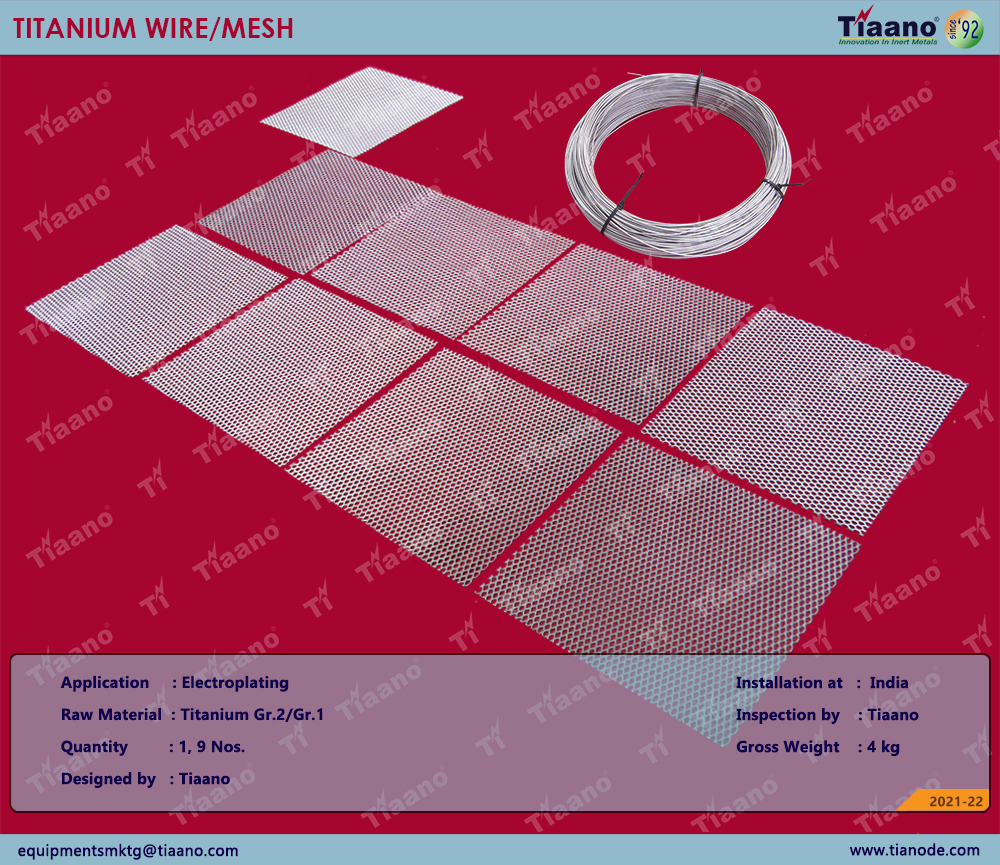

Titanium mesh is made from Titanium, Tantalum, Nickel, and Zirconium are our main focus. Recently we have supplied Titanium mesh to one of our valuable customers and the product photo is attached below.

TITANIUM MESH

To know more details Please feel free to visit our website: - www.tianode.com

Follow Us on Instagram , twitter, Facebook, Pinterest

a0f9766b-eeb5-49db-98a0-a0c63ff6cbdf|0|.0|27604f05-86ad-47ef-9e05-950bb762570c