Caustic soda is the chemical compound sodium hydroxide (NaOH). This compound is an alkali – a type of base that can neutralize acids and is soluble in water. Today caustic soda can be manufactured in the form of pellets, flakes, powders, solutions and more. It corrodes metals, such as aluminum, tin, and zinc. During this process, it generates hydrogen, which has the potential to behave as an explosive gas.

Carbon Steel Piping used for Caustic Service (NaOH content) may be damaged by Caustic Cracking, especially in areas with welded and discrete areas that have high stress. In chemical production, titanium is used as corrosion-resistant material instead of stainless steel, nickel base alloy and other rare metals, which is of great significance in increasing production, improving product quality, prolonging service life of equipment, reducing consumption, reducing energy consumption, reducing cost, preventing pollution, improving working conditions and increasing productivity.

.jpg)

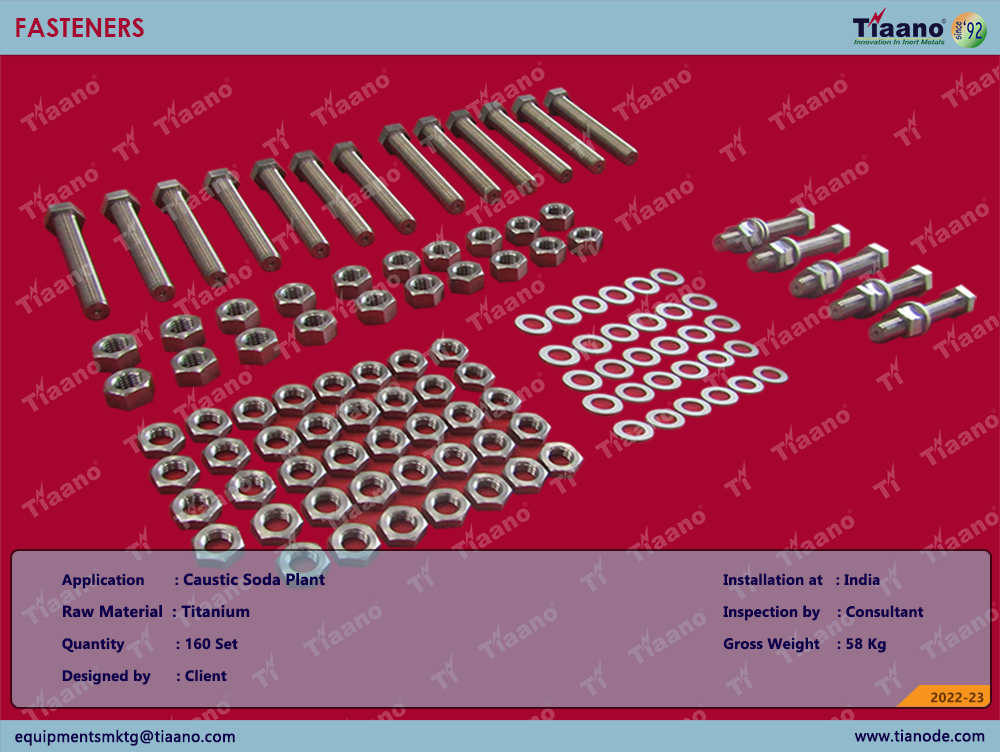

We Tiaano supply Titanium fasteners for different applications. Titanium fasteners are made up of a commercially pure grade of titanium. Titanium Fasteners are used for various application. Titanium fasteners are not only strong, but also lightweight. In terms of strength, it is almost 4 times stronger in comparison stainless steel. The best features of Titanium Fasteners includes its excellent strength to weight ratio & its inert behavior to chlorine containing compounds and seawater. Metals and alloys most frequently considered for use in caustic soda are carbon steel, stainless steels, nickel and high- nickel alloys. Depending on concentration, temperature and impurities, a wide range of alloys may be considered for use in caustic service. Increasing nickel content improves the resistance of stainless and nickel alloys to caustic. Commercially pure nickel alloys 200 and 201 are the most resistant to caustic corrosion and are widely used. Pure nickel alloys also appear to be immune to caustic embrittlement. Duplex stainless alloys also show resistance to caustic and caustic cracking. Alloy 2205 is useful up to 60% concentration at 90° C with no evidence of caustic cracking. Super duplex alloys like ZERON® 100 will offer slightly greater resistance than 2205, which benefit from higher chromium and nickel levels. Titanium alloys can be resistant up to about 40% concentration and below 80° C. Generally, titanium is less resistant than alloy 200. Zirconium alloys offer resistance up to 50% and 60° C. Tantalum is not resistant to caustic solutions.

ff8200ea-375e-4bf6-a4f1-d19d81af2f8e|0|.0|27604f05-86ad-47ef-9e05-950bb762570c