We are very experienced in the customized production of Titanium Pump Body Casing. We provide super quality of Titanium Pump Body Casing, which are designed to meet our customer’s target.

Titanium is now being used in the construction of some pumps and can provide significant benefits. Titanium has excellent corrosion resistance, is compatible with high-chloride level environments, and has a high strength-to-weight ratio. Titanium is 45 percent lighter than steel and twice as strong as aluminum. The titanium also is able to resist abrasive and chemical cavitation erosion, even in high flow environments. Seawater and other high chloride level applications are not the only place where titanium makes sense. It also excels in industrial pumping applications needing to move acidic or chemically aggressive fluids. Titanium pumps have demonstrated a life span 10 times greater than other pumps in the same application, delivering the durability that end-users expect.

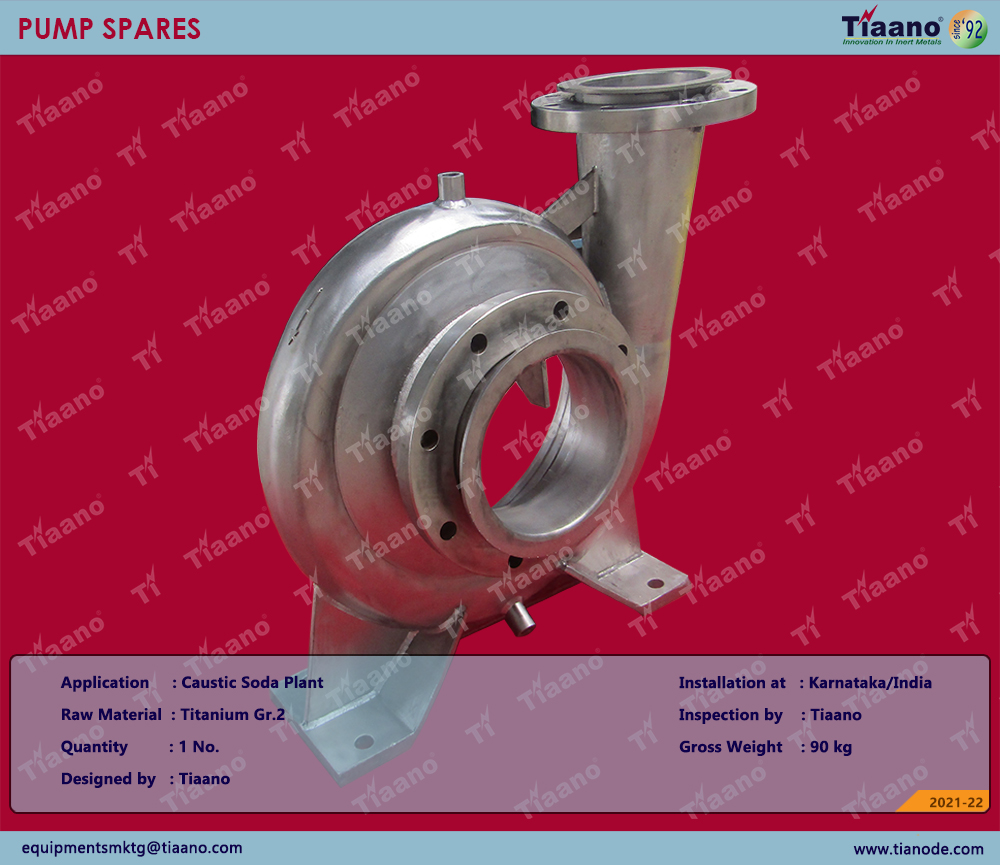

The below-attached photo is for your reference, which was supplied recently to one of our valuable clients.

While titanium is ideal for seawater and other corrosive environments, it has not seen widespread use because of its higher cost. Even though titanium is the ninth most abundant element and the seventh most abundant metal, it is not found freely in nature but rather is found in other minerals from which it needs to be extracted. It is this extraction that results in its higher costs.

To overcome these cost concerns, pump makers have created designs that capitalize on titanium’s dual properties of material strength and corrosion resistance where they are needed. These include motor housings, motor shafts and fasteners. For other less-strength critical areas, engineered polymer materials can be used. These innovative designs have brought unit costs down and spurred the demand for these unique pumps.

To know more details Please feel free to visit our website: - www.tianode.com

Follow Us on Instagram , twitter, Facebook, Pinterest

de78fbb3-a116-47b3-bbf6-22b78b10d06e|0|.0|27604f05-86ad-47ef-9e05-950bb762570c