These Headers are fitted in Titanium Chlorine Cooler Shell& Tube type Heat Exchangers for Caustic and Chlorine Industries. Shell and tube heat exchangers are considered one among the most effective type of heat exchangers. These heat exchangers have a cylindrical shell with a bundle of tubes. The tubes are made from thermally conductive materials, which allow heat exchange between the hot fluids flowing outside the tubes and the coolant flowing through the tubes. These heat exchangers offer an optimal cooling solution to different applications including:

Ä Hydraulic

Ä Leisure

Ä Marine

Ä Rail

Ä Industrial

Shell and tube heat exchangers are widely used in applications, which require cooling or heating a large volume of process fluids or gases. There are a number of different types of shell and tube heat exchanger designs to meet several process needs in every industry.

Important Parts of Shell and Tube Heat Exchangers

The following are the four most crucial parts of a shell and tube heat exchanger:

Ü Tube Bundle: A tube bundle consists of tube sheet sand tubes. The tube bundle is held together by baffles, and tie rods.

Ü Shell: The tube bundle is included in a shell.

Ü Front Header: A front header, which is also referred to as a stationary header, is the part from where the fluid enters the tube side of the exchanger.

Ü Rear Header: A rear header is a part from where the tube side fluid leaves the exchanger or where it is returned to the front header.

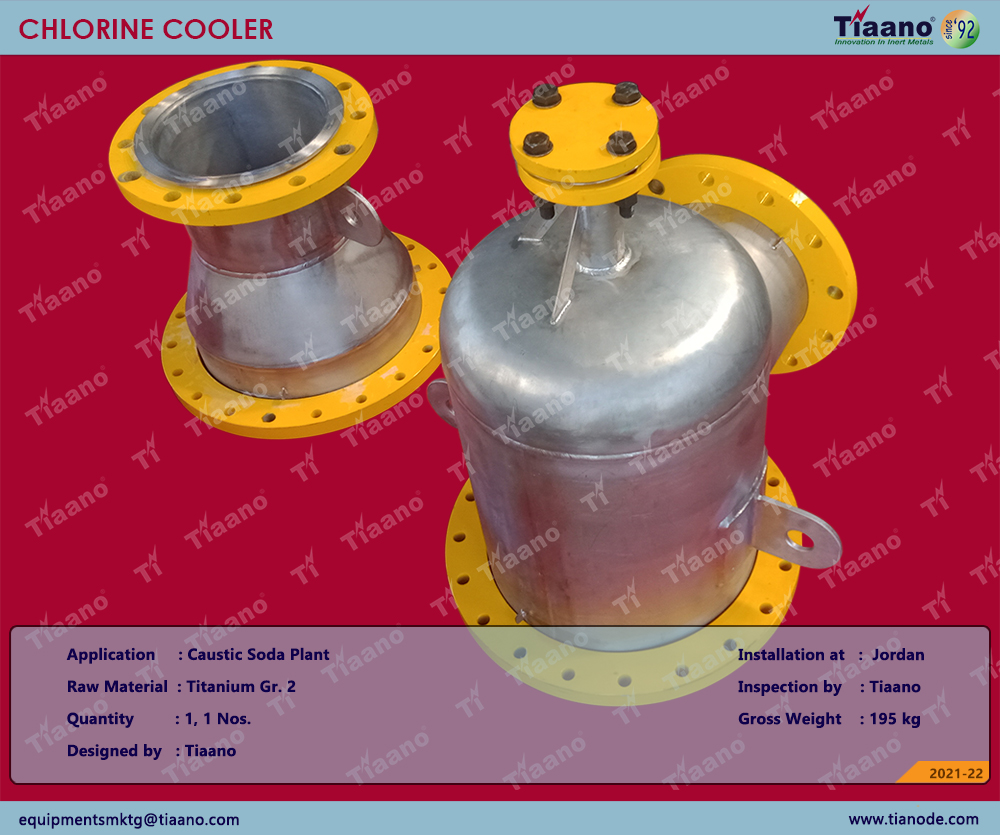

Solid titanium headers – top channel & bottom channelare made from Titanium, Tantalum, Nickel, and Zirconium are our main focus. Ti Anode Fabricators Pvt Ltd has an internationally recognized reputation for the design and manufacture of Solid titanium headers – top channel & bottom channel. We are one of the trustworthy manufacturers, exporters, dealers, and suppliers of titanium headers. Recently we have supplied titanium headers to one of our valuable customers and the product photo is attached below.

TITANIUM HEADERS – TOP CHANNEL & BOTTOM CHANNEL

Shell and tube heat exchanger is used in various industrial process applications because they can perform tasks such as:

v Removal of process heat and feed water preheating

v Cooling of hydraulic and lube oil

v Cooling of turbine, compressor, and engine

v Condensing process vapour or steam

v Evaporating process liquid or steam

Following are some key application areas, where shell and tube heat exchangers are used:

ü Power Generation

ü HVAC

ü Marine Applications

ü Pulp and Paper

ü Refrigeration

ü Pharmaceuticals

ü Air Processing and Compressor Cooling

ü Metals and Mining

To know more details Please feel free to visit our website: - www.tianode.com

Follow Us on Instagram , twitter, Facebook, Pinterest

c7364e32-2e72-40cc-8549-fe3842b5a7e3|0|.0|27604f05-86ad-47ef-9e05-950bb762570c