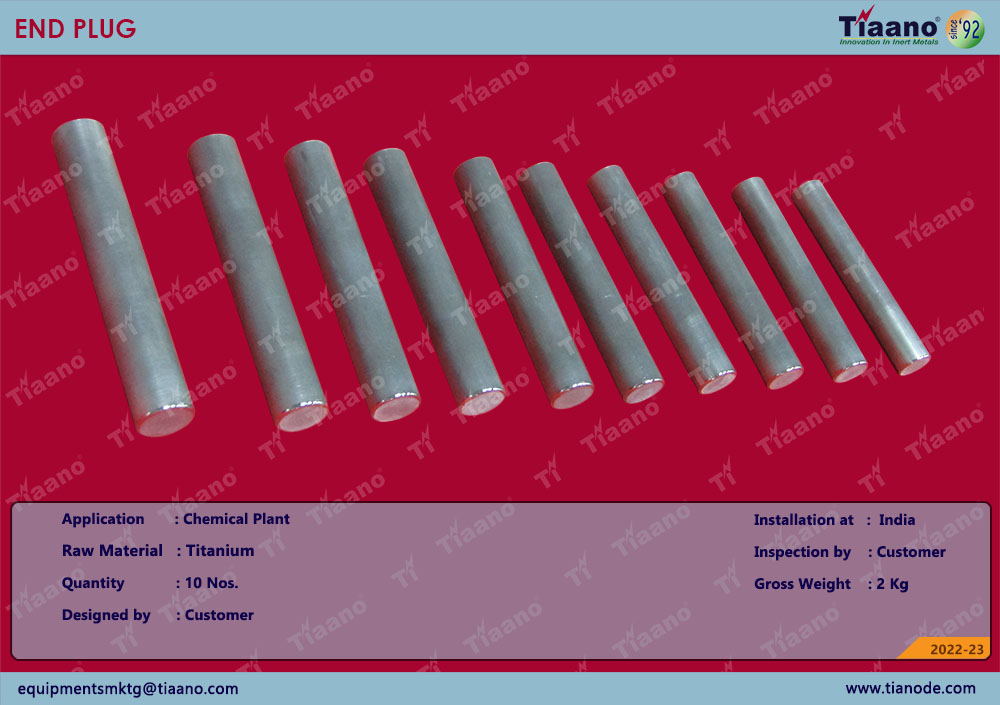

Wide ranges of End Plug are offered by Tiaano from highly corrosion-resistant special materials for the Connectors industries, manufactured in-house from traceable metals, are precision made to the usual international standards.

Tantalum is dark (blue-gray), dense, ductile, very hard, easily fabricated, and highly conductive of heat and electricity. The metal is renowned for its resistance to corrosion by acids; in fact, at temperatures below 150 °C tantalum is almost completely immune to attack by the normally aggressive aqua regia.

More than half of tantalum's use is for electrolytic capacitors and vacuum furnace parts. The element is also used to make chemical process equipment, nuclear reactors, and aircraft and missile parts. Tantalum has found use in making surgical appliances because it's completely immune to body liquids.

Tantalum Applications

· Chemical Processing. Tantalum has excellent corrosion resistance to most acids (a notable exception is hydrofluoric) in a wide range of concentrations and temperatures. ...

· Semiconductors. ...

· Medical Equipment. ...

· Military and Aerospace. ...

· Furnace Applications. ...

· Nuclear Applications. ...

· Electronics Industry.

End Plug are made from Titanium, Tantalum, Nickel, Zirconium, Hastelloy are our main focus.

Our sincere team of professionals and employees are always making an extensive effort to make high range of qualitative products which can be completely satisfy the expectations of our reliable consumers. You can avail this range of Clamps at a very reasonable price and with customer customization. We are proficiency in ethical to the equipment demands in diverse industries including Power, Oil & Gas, and Chemical, Water & Waste Water Treatment, Food, Pharma and others.

Enquiry

For any inquiry in regards to Tantalum End Plug please contact us on +91 8438164458 or email us on equipmentsmktg@tiaano.com.