Ti

Anode

Fabricators P

Ltd

#48,Noothanchery,

Madambakkam,

Chennai - 73, INDIA

Ph: 91 44 22781149 & 1150

Fax : 91 44 22781362

Email :

info@tianode.com

Website : www.tianode.com

|

|

|

|

|

Production

of Chlorine, Caustic, Chlorate & Iodate

We

design, manufacture, maintain & repair the cell, Anodes

& Cathodes for…

Mercury

Membrane

Modular

Diaphragm &

Tank Electrolyzers. |

|

| |

|

|

Electrochemical

engineering is one of the basic keys for many of the products

and processes utilized by today's industrial economies.

Electrode technology is one of the important tools among

the available tools in the electrochemistry. We are the

world's leading supplier of dimensionally stable titanium

anodes, and other related equipments to caustic, chlorine

& chlorate industries using Mercury, Diaphragm, Membrane,

Modular and Tank Electrolyzer cell technology. |

|

| |

Our

Technical and Manufacturing base:

|

Our

online experience, scientific technology, manufacturing

operation, and customer technical service function

to help users improve their Chlor-alkali processes.

A full range of service and technical support programs

is available on the ground of Diagnostic tools and

programs; that can lower operating costs by predicting

residual coating life on working structures. On-site

analysis allows the user to establish a refurbishment

schedule, which minimizes disturbances and maximizes

anode life. If problems occur, our technical auditing

team can conduct the further study on such anodes

either at our plant or R&D center.

|

|

| |

|

Electrodes

and catalyst coatings:

We offer an extensive range of anode and cathode models with

various types of catalyst coatings suited to a host of electrochemical

processes.

The dimensionally stable anode substrate is titanium and the

cathode substrate is normal mild steel, ultra low carbon steel

or nickel.

|

| |

|

Mercury

Cells:

|

Anodes

are manufactured from triangular fingers, strips, expanded,

perforated and grid plates. During the cell operation,

this system allows escaping of gas bubbles, while forming

on active surface. The major factors making long life

of anode catalyst coating & the lowest reliable

attainable K = (Vm2) / (kA) values are:

|

|

Purity

of brine

Cell design & construction.

Cell Temperature.

Anode monitoring & control system. |

|

|

| |

|

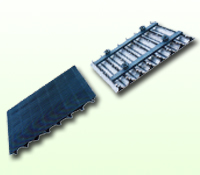

Diaphragm

Cells:

Anodes

are manufactured from expanded metal plates. It allows the

easy flow of electrolytes during operation of cell. Our coating

has proved very well five years life, for the current density

of up to 3.0 KA/m2 and regular operating conditions.

|

| |

|

Membrane

Cells:

| Anodes

are supplied with the fine expanded mesh and when recoating

is necessary, it can be easily removed from base frame.

Our anode catalyst coating works suitably under a wide

range of Ph, with low Cl2 potentials and low O2 contents,

with a guarantee for a long lifetime. |

|

|

|

|

membrane

cell anode

|

copper

cathode for membrane cell

|

|

|

|

|

| |

|

Recoating

/ Refurbishment of Anode:

|

|

|

Removed

the anodes from the cell for Repair and Refurbishment

|

|

|

Our

in-depth, hands-on knowledge of anode recoating

& well-equipped in-plant infrastructures can

help customers prolong the life of expensive anode

structures through repair & recoating, rather

than replacement.

|

|

It

leads double the life of your Anodes with half

of the cost. Almost all anodes can be refurbished

to new specifications; they're used in any electro

chemistry. Refurbishment includes recoating of

MMO, replatinizing, rebuilding the standoff and

/ or replacement, depending on the condition of

the anode.

|

|

Refurbishment

time is only 2-4 weeks. Low current output, damaged

standoffs, leaking seals or damaged mounting threads

are the symptoms of refurbishment.

Further,

to expedite the delivery, TAF

keeps most of the raw materials [like precious metals

of Ru, Ir, Pt, Expanded titanium & Nickel mesh,

plates, rod, wire & pre-prepared Titanium strips

/ runner fingers] in stock for repairing and recoating

of membrane, diaphragm, mercury & Tank Electrolyzer,

Disc and custom made anodes.

|

|

| |

Anodes

after Refurbishment

|

|

| |

|

Customer Relationship:

In-depth experience of our technical team and key persons

in Chlor-alkali cell rooms and on design, fabrication, coating

of precious chemicals & installation of Chlor-alkali cells,

can assist producer's operational problems in the cell house.

For more than 25 years we served a broad range of users, both

domestic and international. Frequent audits are performed

in customer plants to benchmark performance and identify potential

problems.

|

|

|