Ti

Anode

Fabricators P

Ltd

#48,Noothanchery,

Madambakkam,

Chennai - 73, INDIA

Ph: 91 44 22781149 & 1150

Fax : 91 44 22781362

Email :

info@tianode.com

Website : www.tianode.com

|

|

|

|

|

Repair

welding of TAF:

|

Our

fully equipped field service team is ready to tackle any repair

project, equipments made out of Titanium, Tantalum, Zirconium,

and Nickel alloys like Hastelloy, Monel, Inconel, Nicrofer,

X-750, G-30, and Duplex S.S. even in the outside of the clean-room

type environment.

Our experienced welders can handle any type of alteration

repair or modification required, it may be planned shutdown

or is an emergency.

Our

working team is experienced in handling equipments like Plasma

(PAW), Gas Tungsten Arc Welding (GTAW) machines and required

tools; allowing repair activities to be carried out 24 hours

a day.

|

|

Our service is not restricted to our own workshop repair facility.

Qualified technicians and certified welders are available to operate

promptly at the client's plant to perform assembly and make repairs

to critical equipment, components or special items.

The large availability of

TAF

mill products [plates, pipes, forged bars, fittings, welding wire]

in our warehouse is fully supplement for our effective field service.

|

|

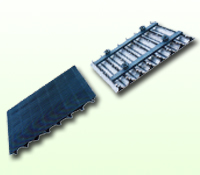

Recoating

/ Refurbishment of Anode:

|

Our

in-depth, hands-on knowledge of anode recoating & well-equipped

in-plant infrastructures can help customers prolong the life

of expensive anode structures through repair & recoating,

rather than replacement.

It

leads double the life of your Anodes with half of the cost.

Almost all anodes can be refurbished to new specifications;

they're used in any electro chemistry. Refurbishment includes

recoating of MMO, replatinizing, rebuilding the standoff and

/ or replacement, depending on the condition of the anode.

|

Refurbishment

time is only 2-4 weeks. Low current output, damaged standoffs, leaking

seals or damaged mounting threads are the symptoms of refurbishment.

Further,

to expedite the delivery, TAF

keeps most of the raw materials [like precious metals of Ru, Ir,

Pt, Expanded titanium & Nickel mesh, plates, rod, wire &

pre-prepared Titanium strips / runner fingers] in stock for repairing

and recoating of membrane, diaphragm, mercury & Tank Electrolyzer,

Disc and custom made anodes.

|

|