Ti

Anode

Fabricators P

Ltd

#48,Noothanchery,

Madambakkam,

Chennai - 73, INDIA

Ph: 91 44 22781149 & 1150

Fax : 91 44 22781362

Email :

info@tianode.com

Website : www.tianode.com

|

|

|

|

|

We

do design, manufacture & test the Electro-chlorinator cell assembly

and its spares for the minimum capacity to produce 15 Gms Sodium

hypo-chlorite per hr. to 1000 Gms. / Hr. for general application

and higher capacity with multifold cell assembly [more than 250

kg/hr.] for industrial / commercial application.

Bi-polar, Mono-polar & Reverse polarization cell is in our scope.

In normal, we do design the anode for 3.5 to 4.0-kwh/kg-cell voltages,

with the coating life guarantee of 3 to 5 years, depends on the

current density and material of construction. Reverse polarization

cells are guaranteed up to 2.0 years, or depend on the operating

conditions.

|

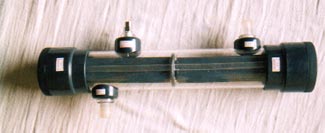

( HORIZONTAL CROSS SECTION OF THE ELECTROLYZER ) |

|

Efficient

production of sodium hypo-chlorite (Naocl) is optimized by

TAF

unique

design utilizing multiple electrode modules. For larger system

capacities, Modular Sodium Hypochlorite electrolytic cells

are to be arranged side-by-side. NaOCL is to produce on-site

as needed at relatively low concentrations, assuring longer

half-life than commercial hypo-chlorite (bleach).

|

(

ELECTRO-CHLORINATOR ELECTRODES )

|

|

Electrodes

consists a set of Anodes & Cathodes, to be manufactured

from ASTM B 265, 337,338 Gr.1 or 2, Plate, Expanded Mesh,

Seamless and seam welded Pipe or Tube, Coated / Plated with

Platinum group of Noble Metals like …Iridium, Ruthenium,

Platinum.

|

|

(ELECTRO-CHLORINATOR)

|

Scope:

|

|

|

electrodes

for 1.0kg / Hr

|

Titanium Cell Assembly (anode & cathodes).

Required Brass & Titanium fasteners.

Housing is clear PVC for drawing no. 195, 196 & 197

Housing is titanium for drawing nos. 198, 199 & 200

Our standard electrolyzers and its operating

parameters are referred in the enclosure. |

| |

|

General

Cell Maintenance

All

cells require cleaning. This must be carried out before the

calcium buildup within the cell housing becomes one big block

(6-8 months gap). Left for too long it will do two things.

Break

the cell housing.

Shorten the cell life.

Using

a diluted solution of hydrochloric acid and water can do cleaning.

The dilution of acid to water should be 1 (one) part acid

and 8 (eight) parts water, mixed in a separate container,

then poured into your cell cleaning container. The cell cleaning

process can take between 15 minutes and a few hours, depending

on how much scale is on the cell. The cell must be completely

free of any scale and rinsed in clean water by Jet (high pressure).

On average, the cell will need to be cleaned every four weeks.

|

| |

Test

Certificates to be submitted:

1. Mechanical & Chemical analysis certificate for titanium

Gr.2

2. Bend & Thickness test certificate for MMO-special- (6

micron) coating on titanium.

3. Leak test certificate for Cell Housing |

| |

|

List

of Spares:

Following

parts are also to be supplied as a spares, based on your request.

|

|

Titanium

or Stainless or Nickel Anodes & Cathodes. |

|

Fasteners

- like Stud, Nut, and Washer & Pin out of Titanium, Brass,

Stainless Steel, and Copper. |

|

Titanium

Heat Exchanger - Hypochlorite cooler (bayonet, Coil type, Shell

& tube design) to maintain the temperature of electrolytes

between 25 to 30 degree C. |

|

Titanium

Nozzles for Hydrogen Vent. |

|

Titanium

Storage Tank and Mixture for Salt Blending. |

|

Fabricated

Titanium Centrifugal Pump for brine handling. |

|

Titanium

Ball Valves. |

|

Titanium

Thermowells or Safety Packet for temperature measurement sensor.

|

|

CPVC

/ Clear PVC / GRP Cell Housing & Heat Exchanger Housing. |

|

PTFE

/ Teflon or PVC Spacers. |

|

Refurbishment

of the existing electrolyzer:

It

leads double the life of your Electrolyzers with half of the

cost.Almost all Electrolyzers can be refurbished to new specifications;its

cost will be just half of buying new one.

Refurbishment include recoating, rebuilding the standoff and

/ or replacement, depending on the condition of the Electrolyzers.

Refurbishment time is only 2-4 weeks. Low current output,

damaged standoffs, leaking seals or damaged mounting threads

are the symptoms of refurbishment.

Our

in-depth, hands-on knowledge of anode recoating & well-equipped

in-plant infrastructures can help customers prolong the life

of expensive anode structures through repair & recoating,

rather than replacement.

Further

to expedite the delivery of refurbishment, TAF

keeps most of the rawmaterial like precious metals (Ru, Ir,

Pd, Expanded titanium & Nickel mesh, plates, rods, wires

& pre0prepared Titanium strips / runner fingers) in stock.

We

done the refurbishment of the existing electrolyzers, manufactured

by the world leaders, like SESPI, DENORA, US FILTER, DECUSA,

METAKEM, HERAOUS, OSG and Etc.

|

| |

|

Guarantee:

The

electrodes are to be operational guaranteed for the period

of 5 years, from the date of our billing. If the cells are

to be operated by reverse polarity, its life guarantee is

max. 2 years.

|

|

|