Ti

Anode

Fabricators P

Ltd

#48,Noothanchery,

Madambakkam,

Chennai - 73, INDIA

Ph: 91 44 22781149 & 1150

Fax : 91 44 22781362

Email :

info@tianode.com

Website : www.tianode.com

|

|

Electrodes

| Chlor

Alkali | Electro

Chlorination | Cathodic-Protection

| Platinised

Ti/Nb |

Recoating

/ Refurbishment | |

|

TITANIUM

FOR SHIPS

|

|

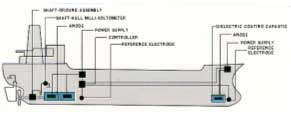

The

leading anti-corrosion, outstanding physical & mechanical properties

of titanium and its alloys are suited for condensing / chilling

the seawater and seafood storage. As titanium has the mechanical

stability and uniform current distribution character, Platinised

anodes and MMO coated anodes are to be manufactured from Titanium

for marine ICCP & Electrolyzer for electro chlorination. However,

we offer the following for the Ship industry.

|

| |

|

MMO

/ Platinised Disc & Strip Anodes are developed specifically

for protection of Dam and Navigation lock gates. Since

our disk anodes are designed to operate in fresh, brackish

and seawater environments, it is to be used in other

suitable applications include: marine structures, water

tanks, and vessels. With an optional primary seal spacer

gasket, it can be used on the inside of pipes, pumps,

water tanks, or other curved surfaces.

|

MMO and Platinised Disc Anode |

|

Availability:

Disc

anodes are available from 5 IN to 12 IN & Strip

anodes are typically available 2 to 3" wide and

6 to 16" long. Special size anodes also mfd. as

per customer's requirements.

|

Anode Installation |

|

Refurbishment:

It

leads double the life of your Anodes with half of the

cost. Almost all anodes can be refurbished to new specifications,

whether they're used in Water boxes, Marine structures

or and Pressure vessels. Its cost will be just half

of buying new one. Refurbishment include replatinizing,

rebuilding the standoff and / or replacement, depending

on the condition of the anode. Refurbishment time is

only 2-4 weeks. Low current output, damaged standoffs,

leaking seals or damaged mounting threads are the symptoms

of refurbishment.

|

Platinised disc with Rubber Casing |

Sacrificial

Anode system

Require …

|

|

Replacement

up to 10 times |

|

|

10

periods of downtime |

|

|

10

repair bills |

|

|

10

times dry - docking |

|

MMO

Disc with GRP Casing |

|

|

| Specifications: |

|

Particulars

|

Anode

|

|

Design Parameters:

Max. Flow Rate

|

40 ft/sec

|

|

Pressure Rating

|

50 psi

|

|

Max. Operating Temp.

|

140 F

|

|

Max. Excursion Temp.

|

200 F/hr.

|

|

Substrate selection:

Less than 10v (high conductivity

Waters) like seawater.

|

Titanium

|

|

More than 10v

|

Niobium

|

|

Coating selection:

CD is below 10 A/ft2 in brackish or

fresh water environments.

|

Platinum

|

|

If Chlorine is generated at the anode

surface.

|

Platinum

|

|

If Oxygen evolution is expected at the

Anode surface like fresh water

|

MMO Surface

|

|

| ELECTROLYZER

FOR ON-SITE SODIUM HYPO-CHLORITE GENERATOR |

|

On-site Sodium Hypo-Chlorite Generator is the best solution

to the Chlorination Equation. It generates active Chlorine

(Sodium Hypo chlorite) on- site, from brine or seawater,

as needed at relatively low concentrations, assuring

longer half-life than commercial hypo (bleach). As a

disinfectant, Sodium Hypochlorite performs as well as

Chlorine but it is far less hazardous.

|

|

50 grm/hr capacity Electrolyzer

In passengers Ship |

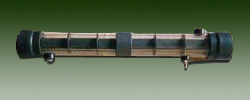

Cell

Design & Construction:

Efficient

production of sodium Hypochlorite is optimized by our

unique design of titanium electrode modules.

Electrodes

consists a set of Anodes & Cathodes, to be manufactured

from ASTM B 265, 337,338 Gr.1 or 2, Plate, Expanded

Mesh, Seamless and seam welded Pipe or Tube, Coated

/ Plated with Platinum group of Noble Metals like …Iridium,

Ruthenium, Platinum.

|

|

Bi-polar,

Mono-polar & Reverse polarization cell assembly

is in our scope. In normal, we do design the anode for

3.5 to 4.0-cell voltage, with the coating life guarantee

of 3 to 5 years, depends on the current density and

material of construction [sheet, mesh or pipe].

An R.P cell is guaranteed up to 1.5 years, or depends

on the operating conditions.

|

1000

grm/hr capacity Electrolyzer in

Fishing ship

|

|

|

Features:

Safe:

No hazardous gas to handle or store.

Friendly environment:

No hazardous chemicals are produced or used.

Easy to operate & Maintain:

It requires little training for operation & maintenance.

Field Proven: For more than 23 years our technology has

performed reliably in all over the world.

Easy to operate & Maintain:

From project specifications to after sale support, we provide

responsive service for the life of your project.

Customised System:

Electrolyzer is available "off - the-shelf" in

a wide range of capacities. We do engineering and builds

systems to exactly match your requirement.

|

TOP

|

TITANIUM

CHILLER COIL

For marine Chiller |

|

Wide

range of Heat exchanger coils and Shell & Tube exchangers

are offered by TAF

are precision made to the usual standards up to ASME.

For Marine Refrigeration, Chilling of Brine/sea water

& cool the hypo, We do offer Titanium ERW / Seamless

/ Fabricated tube or pipe confirming, as per ASTM B

337 or 338 Gr.2 for cooling coils and sensor safety

pockets. We do conduct Custom design, ASME IX Coded

welding, NACE stress relieving facilities, Computerized

Corrosion analyses of rawmaterial, Pneumatic test up

to 8.0 kg/cm2, Dye penetrates & Radiography tests.

Coils are available in stock.

|

Titanium coil for marine Chiller |

|

Specifications:

| Outer

diameter |

3.0

inch (Min) |

| Inner

diameter |

2.0

inch (Min) |

| Tube/pipe

diameter |

3/8

inch (Min) |

Tube

length with out

Joints

|

6.0

mtrs |

Coil

Pitch

Coil Length

Number of turns |

As

required

As required

As required |

| Rawmaterial |

ASTM

B 338/337 |

| Test pressure |

6kg/cm2 |

|

'U' & Custom made coils |

|

Material:

TAF

offers the coils from variety of metals, like

- Titanium

& its alloys.

- Tantalum,

Niobium, Zirconium & their alloys.

- Nickel

& its alloys like Hastelloy C & B, C4,2000,

Monel, & Inconel.

- SS

304, 316, 321 & Duplex.

- Oxide

layer provision to prevent the crevice corrosion

|

Feature:

- Custom

design.

- ASME

IX Coded welding.

- NACE

Stress relieving facilities.

- ERW

/ Seamless / Fabricated Pipe.

- Traceable

metals from single roof.

- Computerized

Corrosion database.

- Pneumatic

test up to 8 kg / cm2 for two hours.

- Dye

penetrates & Radiography test as required.

- Nipple

end connections.

|

|

|

| TITANIUM

STORAGE TRAY FOR MARINE HARVEST |

|

We

manufactures an extensive range with the highest specification of

Titanium storage equipments of tray, tank & many. They are the

vital elements in marine storage, because of the special chemical,

physical properties, high corrosion resistance, erosion resistance,

heat transfer efficient and superior strength to weight ratio of

titanium. Storage equipments are available in standards as well

as customs design, manufactured from commercially pure titanium,

confirming to ASTM B 265 Gr. 1 or 2.

|

|